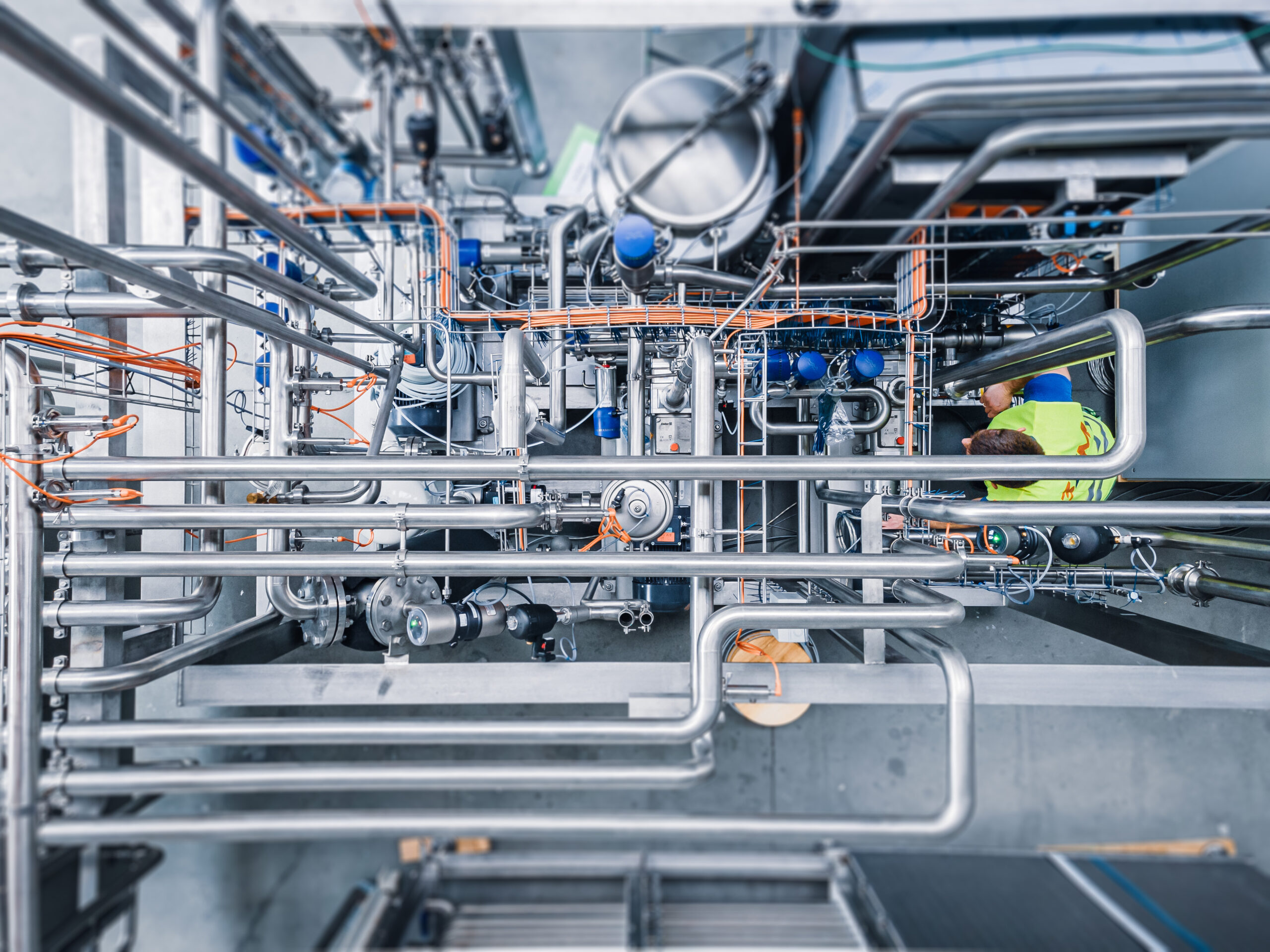

Optimizing media consumption is a key task for every production. Our heat recovery systems, equipped with tank-based thermal energy accumulators, help reduce energy consumption in your plant. With these solutions, you can:

• Easily integrate systems into existing production without having to make significant changes to the technological process.

• Maintain current production technological parameters, ensuring continuous process and stability.

• Reduce steam and chilled water consumption, what leads to operational costs reduction and to reduction of carbon footprint.

With the help of digital modeling and mathematical analysis, our heat recovery systems are able to ensure maximum energy efficiency of your plant.

An effective CIP and sanitation station is essential for any production. Our design and construction teams create CIP stations that are fully customized to your needs, with future expansions taken into account at the design stage. We extend existing systems with additional routes and provide dedicated CIP solutions for membrane plants and other production areas. We work with leading chemical suppliers to optimize your CIP processes and increase their efficiency, ensuring the highest standards of hygiene and quality.

Our modern control systems provide full process automation, precise production management, and remote monitoring and online support. By using IoT technology and integrating with Internet, we maximize the efficiency and safety of your production.

KEY FUNCTIONS OF OUR SYSTEMS:

• Full automation: intelligent control of all production stages, ensuring efficiency and precision.

• Remote monitoring: access to real-time data from anywhere, enabling immediate response to changes.

• Online diagnostics: fast analysis and technical support via the Internet, reducing downtime and increasing system availability.

• Energy optimization: control of heat recovery and process efficiency, transferring to cost savings and reduction of carbon footprint.

• Security and compliance: precise quality control and reporting, ensuring compliance with industry norms and standards.

Our multi-wall tanks, equipped with a cooling and thermal insulation function, are specially designed for the phase change of lactose (mutarotation process). Thanks to this, the whey loses its hygroscopic properties, which significantly facilitates the drying process and storage of the finished product. The process involves slow cooling using ice water and mixing, what allows the lactose to be transformed into the appropriate form.

KEY FEATURES OF OUR CRYSTALLIZERS:

• Process tank and agitator: designed specifically for products of this nature, ensuring an efficient and controlled process.

• Lateral, extendable washing heads: enables a thorough and repeatable cleaning process (CIP), which is essential for maintaining the highest hygiene standards.

• Service platform and process automation: available as a set to ensure convenience and efficiency in process management (optional equipment).

• Individual selection of quantity and capacity: crystallizers are selected for the daily whey processing in your plant, with volumes from 4 to 25 m³ and the possibility of any extra arrangement.

• Collector solutions: available as boards or automatic collector, adapted to the individual requirements of the customer.

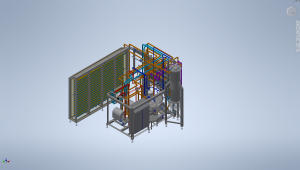

We offer advanced spray dryers designed for the highest efficiency of the process. Our technological solutions allow to produce standard powders, agglomerated products and products with a high fat content – up to 50%.

KEY FEATURES OF OUR DRYERS:

• Capacity range: from 50 to 3000 kg/h by evaporated water, allowing adaptation to different production needs.

• Spraying methods: nozzle or disc, allowing process optimization depending on the product.

• Powder moisture: 3-5% (or according to the Customer’s specification).

• Exhaust air filtration: through hygienic bag filters (emissions below 10 mg/m³), guaranteeing the highest standards of cleanliness.

• Process air drying

• Heat recovery/recuperation systems, reducing costs and carbon footprint.

• Multi-stage dryers: with powder drying, lecithinization and cooling functions, allowing for comprehensive product processing.

• Automatic CIP cleaning: of all dryer parts, ensuring efficiency and hygiene.

• Process automation: visualization and archiving of process parameters, allowing for precise control and optimization.

• Reconstruction of existing dryers: into modern technological units, increasing efficiency and productivity.

• MVR and TVR evaporators: available in our offer.

TYPICAL APPLICATIONS:

• Food ingredients

• Yeast products

• Plant extracts

• Agricultural chemicals

• Tanning agents

• Dyes

• Fertilizers

• Detergent ingredients

Our dryers combine advanced technology with ease of operation, ensuring precise control of all stages of production and customization to individual customer needs.

There is a constant need in food processing plants to efficiently dose liquid or powder ingredients. Our solutions are designed to meet these requirements, offering a wide range of mixing systems and engineering support in selecting the best method for implementing the process.

DOSING METHODS:

• In-line dosing: before the filling machine, allowing precise and continuous dosing of ingredients directly in the production line.

• Batch dosing: in tanks, ideal for batch processes, where the quantity and quality of ingredients in each batch can be controlled.

• Flow dosing: with automatic changeover of ingredients, providing flexibility and efficiency in the production process.

CUSTOMIZATION AND INTEGRATION:

Each of our solutions can be customized and combined to optimize production processes. Our systems guarantee the highest efficiency and product quality, making them ideal for the food industry.

Protein standardization is a key process in the dairy industry, providing optimization of mass balances, increasing efficiency and plant profitability. Our protein standardization systems are designed with the specifics of production in mind to ensure maximum efficiency and the best results.

KEY SOLUTIONS:

• Adaptation to the type of production: protein standardization systems are designed differently for fermented beverage plants and cheese plants, allowing for process optimization based on exact needs.

• Equipment configuration: our solutions are adapted to the equipment configuration in the plant, ensuring full integration and efficiency.

• Production specificity: systems are designed with the specificity of production in mind, to ensure maximum efficiency and quality of the final product.

Precise fat standardization is a key element of modern production, ensuring that products always meet the required parameters in an optimal and efficient manner. Our systems are designed to adapt to individual customer needs, using all proven methods.

KEY BENEFITS:

• Precision and stability: our modules guarantee constant and precise control of fat content, which is extremely important in food production and other industries.

• Flexibility: the systems are adapted to different production processes, allowing customers to choose the best method for their specific needs.

• Efficiency: our solutions are optimized for maximum efficiency and minimum costs, which translates into increased competitiveness of customers in the market.

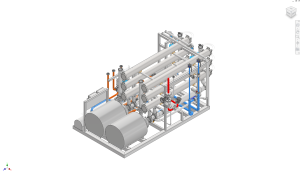

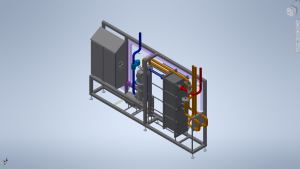

We are a leader in the design and production of advanced filtration systems for the food industry, tailored to individual customer needs.

We use four key filtration technologies:

• Reverse osmosis (RO): water concentration and recovery, enabling effective control of water resources.

• Nanofiltration (NF): separation of salts and nutrients, allowing for obtaining products with a specific composition.

• Ultrafiltration (UF): protein standardization and production of fermented products, ensuring the stability and quality of the final product.

• Microfiltration (MF): bacteria removal and microbiological stabilization, ensuring the safety and durability of products, protein fractionation.

COMPLETE SOLUTIONS:

We create complete filtration systems for milk processing, whey and powders production, combining technologies into optimal systems. Our innovative systems increase production efficiency and quality, providing customers with a competitive advantage in the market.

At 3XM, we offer a wide range of UHT solutions, tailored to the diverse needs and applications in the food industry. Our UHT modules are designed to ensure the highest quality and durability of products, while maintaining their natural properties.

UHT SOLUTIONS:

• Indirect heating: our plate and tube UHT systems are ideal for a variety of applications, providing efficient and controlled heat treatment.

• Direct heating: UHT injection and infusion units allow for the efficient treatment of a wide range of products, preserving their taste and aroma

In the process of selecting the best solution, we analyze all available variants and product specifics to provide the optimal solution or combination of solutions, tailored to your needs. Our UHT modules are designed with the latest technologies and hygiene standards in mind, which allows for obtaining products of the highest quality and durability.

PASTEURIZATION

At 3XM we specialize in pasteurization, offering comprehensive solutions tailored to the individual needs of our customers. Our experience allows us to provide optimal solutions, minimizing chemical, physical and organoleptic changes in products.

COOLING

After pasteurization, cooling to the required temperature takes place. We take into account local traditions and regulations to create an optimal process.

TECHNICAL SOLUTIONS:

We offer a variety of pasteurization units, including those based on:

• Plate heat exchangers

• Tubular heat exchangers

• Scraper heat exchangers

Our systems provide precise temperature control, which is crucial for maintaining high product quality after the pasteurization process. Effective cooling allows for extended shelf life of products, minimizes the risk of microbial growth and ensures food safety.

Specialising in processing all types of dairy products, we offer a wide range of coolers to suit different product types, including protein and fat content, density and viscosity.

WE OFFER:

• Plate coolers: ideal for fast and efficient cooling, available in a variety of sizes and configurations to meet individual customer needs.

• Tubular coolers: providing precise temperature control and optimal heat transfer, which is essential for maintaining product quality.

• Scraped surface heat exchangers: offering higher efficiency and flexibility in the cooling process, ideal for products requiring specialized processing.

INTEGRATION AND SERVICE:

Our teams can calculate, manufacture and integrate coolers into existing production systems, ensuring full compatibility and efficiency. Our solutions are tailored to the specifics of your products to ensure the highest quality and durability.

MILK RECEPTION UNITS

Milk reception units are the backbone of any dairy, so it is important that collection is carried out quickly, efficiently and with excellent traceability. Our units are available in different capacities, from 10,000 to 100,000 l/h, allowing for customization and individual customer needs.

KEY FEATURES:

• Standard solutions: can be supplied in a standard configuration or based on customer specific requests, taking into account local regulations and requirements.

• Sampling equipment: we supply on request, ensuring full control of the milk quality.

• Efficiency and speed: our stations are designed to maximise milk collection efficiency, which translates into increased productivity.

05-250 Radzymin,

ul. Przemysłowa 5